Madder Root Dyed Vintage Crochet Lace

Madder Root Dyed Vintage Lace and Trims

Vintage lace and trims I picked up at a yard sale this summer, some are antiques. Everything has been scoured by washing twice in hot water - to get rid of the smell, then boiled with soda ash for two hours. The items were then mordanted with alum and soaked for two days in the alum vat, I then dyed everything with Madder Root Extract I left them to soak in the madder root vat for two days. The brighter yellow items are made of nylon hence the color.

Vintage lace and trims I picked up at a yard sale this summer, some are antiques. Everything has been scoured by washing twice in hot water - to get rid of the smell, then boiled with soda ash for two hours. The items were then mordanted with alum and soaked for two days in the alum vat, I then dyed everything with Madder Root Extract I left them to soak in the madder root vat for two days. The brighter yellow items are made of nylon hence the color.Today's Dye Session

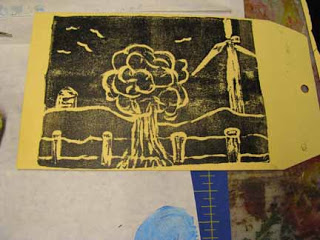

Foam Tray Mono Prints

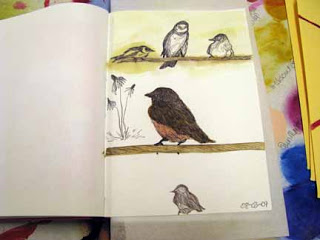

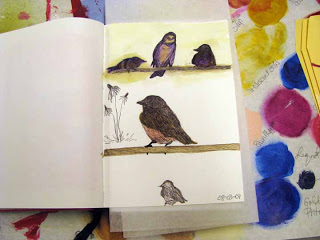

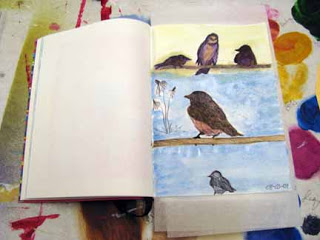

Birds

Garden Fresh!

Birds on a Wire

Birds on a Wire - Sketches

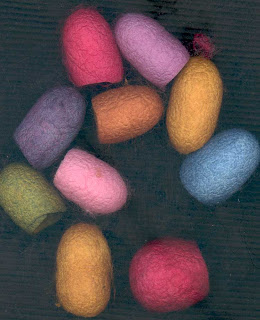

Natural Dyed Silk Cocoons - Mulit Colors

Pickles

Wow it's been awhile since I've posted so to update

We've eaten two tomatoes out of our garden, they were very tasty and we are eagerly awaiting the arrival of more ripe tomatoes hopefully in the next week or so. First up on the list of canned tomato goods is salsa, it's been years since I've canned any because well it's been years since I've had any "real" tomatoes to speak of!!! We'll also make up and can our own spagetti sauce, pizza sauce, and if there are enough tomatoes ketchup and bbq sauce. I have plans, at the end of the season , to can green tomato slices for my fried green tomato cravings over the winter months.

I've been picking green beans, planted Top Crop, and cucumbers like crazy. So far we've put up 31 pints of green beans and have eaten several pickings of beans - they are best fresh what can I say!

The cucumbers, I planted a pickler varitety, are coming on strong, this year I plan to make lots of lime pickles as these were a hit here this past winter and I'm hoping to try my hand at my first ever batch of dill pickle relish!

I found out why my potatoes were size of peas, not enough water, turns out they need a half inch a week or so, soooooooo I've upped my watering routine. Turns out this is why ALL of my root crops are doing poorly, lack of water. I have some really pretty green tops though ;-)

John replanted Rhutabegas and Beets tonight there's still plenty of growing time in our season for the year yet. While he was weeding the garden he found two volunteer tomato plants, one looks to be a Rutgers the other some sort of cherry tomato. Barring any rain I'll plant Kale tomorrow and maybe some more chard and lettuce., in fact I think it's early enough to replant cucumbers and maybe even a zucchini plant or two.

We've eaten two tomatoes out of our garden, they were very tasty and we are eagerly awaiting the arrival of more ripe tomatoes hopefully in the next week or so. First up on the list of canned tomato goods is salsa, it's been years since I've canned any because well it's been years since I've had any "real" tomatoes to speak of!!! We'll also make up and can our own spagetti sauce, pizza sauce, and if there are enough tomatoes ketchup and bbq sauce. I have plans, at the end of the season , to can green tomato slices for my fried green tomato cravings over the winter months.

I've been picking green beans, planted Top Crop, and cucumbers like crazy. So far we've put up 31 pints of green beans and have eaten several pickings of beans - they are best fresh what can I say!

The cucumbers, I planted a pickler varitety, are coming on strong, this year I plan to make lots of lime pickles as these were a hit here this past winter and I'm hoping to try my hand at my first ever batch of dill pickle relish!

I found out why my potatoes were size of peas, not enough water, turns out they need a half inch a week or so, soooooooo I've upped my watering routine. Turns out this is why ALL of my root crops are doing poorly, lack of water. I have some really pretty green tops though ;-)

John replanted Rhutabegas and Beets tonight there's still plenty of growing time in our season for the year yet. While he was weeding the garden he found two volunteer tomato plants, one looks to be a Rutgers the other some sort of cherry tomato. Barring any rain I'll plant Kale tomorrow and maybe some more chard and lettuce., in fact I think it's early enough to replant cucumbers and maybe even a zucchini plant or two.

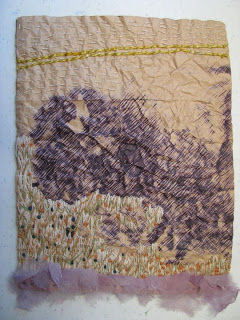

Purple Bison

I started this piece several years ago, click here, I'll have to search the archives to find the first post on this piece. I found it in a drawer last night and decided it needed finishing!

I started this piece several years ago, click here, I'll have to search the archives to find the first post on this piece. I found it in a drawer last night and decided it needed finishing!Digital print on brown craft paper (paper bag actually)

Logwood dyed silk chiffon

Linen and hemp threads dyed with natural dyes

8x10 inches

Windmill

Updated Zine

I just updated The Natural Surfaces Zine with indigo dyeing instructions, I'll try to get more video uploaded to youtube on how to use a fermentation vat, now that my computer is working once again, in the near future. http://thenaturalsurface.blogspot.com/ The instructions are for the traditional indigo lye vat (NOTE you can substitute soda ash for the lye which is what I highly recommend).

Basic Natural Dyeing Safety

Dye Safety

Copyright 2003

Kimberly Baxter Packwood

Never assume that because it’s a natural dye that it’s safe!

Many people have allergies to grasses, weeds, flowers and trees.

IF you are a highly sensitive/allergic person then be sure of what you are dyeing WITH before dyeing.

IF you have severe allergies consult with your doctor prior to dyeing with grasses, flowers, tree parts, or any unknown or known weed.

Always work in an area that is designated for studio/dye work.

Never use dye materials, mordants or other dyestuffs in your designated cooking areas!

Use only dedicated dye equipment that is used for dyeing/surface design only. Never use this equipment for cooking food for human consumption.

Use a high quality respirator when handling dye extracts and mordants.

Work in an adequately ventilated area.

Copyright 2003

Kimberly Baxter Packwood

Never assume that because it’s a natural dye that it’s safe!

Many people have allergies to grasses, weeds, flowers and trees.

IF you are a highly sensitive/allergic person then be sure of what you are dyeing WITH before dyeing.

IF you have severe allergies consult with your doctor prior to dyeing with grasses, flowers, tree parts, or any unknown or known weed.

Always work in an area that is designated for studio/dye work.

Never use dye materials, mordants or other dyestuffs in your designated cooking areas!

Use only dedicated dye equipment that is used for dyeing/surface design only. Never use this equipment for cooking food for human consumption.

Use a high quality respirator when handling dye extracts and mordants.

Work in an adequately ventilated area.

Stirring the Indigo Fermentation Vat

Here you can see the madder root, which has yet to break down, under the indigo water's surface the water has a blue foam on the top but has not turned a dark blue yet. This vat requires more fermentation time before it will become usable.

Here you can see the madder root, which has yet to break down, under the indigo water's surface the water has a blue foam on the top but has not turned a dark blue yet. This vat requires more fermentation time before it will become usable. The vat will start out dark blue color you will need to beat air into the vat to get it to reduce at this time. Beating the indigo fermentation vat seems to defy all logic when it comes to indigo dyeing - where you are constantly being told to NOT introduce Oxygen into the vat, this is the one time you get to stir the dickens out of your indigo vat and it results in great colors!

The vat will start out dark blue color you will need to beat air into the vat to get it to reduce at this time. Beating the indigo fermentation vat seems to defy all logic when it comes to indigo dyeing - where you are constantly being told to NOT introduce Oxygen into the vat, this is the one time you get to stir the dickens out of your indigo vat and it results in great colors!Indigo Fermentation Vat

Natural Indigo Fermentation Vat

Copyright 2006

Kimberly Baxter Packwood

Natural Indigo Fermentation Vat Mini-Vat Instructions

1.0 ounce Natural Indigo Ground

0.5 ounce Madder Root cut into fine pieces

0.5 ounce Bran (Wheat works best, Oat will also work)

3.0 ounce Soda Ash

Stainless Steel, or Enamel, Pot. A plastic bucket may be substituted for the pot, be sure that has a tight fitting lid.

Place warm water, not boiling, into pot, preferably one that holds more than 2 gallons of water.

WARNING: Wear respirator when working with ground indigo, anything in powdered form will float easily in the air making it easily inhaled. This is not good for your lungs!

WARINGING: Soda Ash is highly caustic, wear gloves and dust mask when handling soda ash. Avoid contact with skin.

Dissolve ground indigo in warm tap water, enough to cover and make a rough paste.

Note: The ground Indigo will float at the top of the vat if just thrown into the water make your paste first. The indigo at this point is not completely dissolved, once introduced to the vat; it will dissolve after a few days in the vat.

Add madder root, bran, and soda ash to the warm water stir well then add indigo paste to the vat. Cover, but not tightly, and apply heat source.

Stir the pot once, or twice, a day during the reduction period with one gentle stir. If you stir the vat too often this will introduce Oxygen into the vat.

Depending on where you live, i.e., temperature and humidity levels, the vat can take anywhere from 5 – 10 days to become viable. By viable I mean ready to dye fibers.

Fermentation vats need to be kept warm while reducing. I keep my vat, a stainless steel pot that is covered with a lid, in my studio oven (gas) where the pilot light is continuously on, about 98 degrees F.

The vat needs to be kept at body temperature during the reduction phase.

If you do not have a dedicated oven, I recommend using either a heating pad, with a temperature control knob, or a high quality fish tank heater with digital temperature controls.

Chopped Madder Root

Chopped Madder Root

The Bran now added to the vat. The bran floats on top of the madder root until they have been sufficiently stirred together, eventually sinking to the bottom of the vat.

The Bran now added to the vat. The bran floats on top of the madder root until they have been sufficiently stirred together, eventually sinking to the bottom of the vat.

Soda Ash has now been added to the vat. The vat has a foamy look from the bubbling action of the soda ash. The mixture has been blended, to ensure that the soda ash does not solidify on the bottom of the bucket.

Soda Ash has now been added to the vat. The vat has a foamy look from the bubbling action of the soda ash. The mixture has been blended, to ensure that the soda ash does not solidify on the bottom of the bucket.

Copyright 2006

Kimberly Baxter Packwood

Natural Indigo Fermentation Vat Mini-Vat Instructions

1.0 ounce Natural Indigo Ground

0.5 ounce Madder Root cut into fine pieces

0.5 ounce Bran (Wheat works best, Oat will also work)

3.0 ounce Soda Ash

Stainless Steel, or Enamel, Pot. A plastic bucket may be substituted for the pot, be sure that has a tight fitting lid.

Place warm water, not boiling, into pot, preferably one that holds more than 2 gallons of water.

WARNING: Wear respirator when working with ground indigo, anything in powdered form will float easily in the air making it easily inhaled. This is not good for your lungs!

WARINGING: Soda Ash is highly caustic, wear gloves and dust mask when handling soda ash. Avoid contact with skin.

Dissolve ground indigo in warm tap water, enough to cover and make a rough paste.

Note: The ground Indigo will float at the top of the vat if just thrown into the water make your paste first. The indigo at this point is not completely dissolved, once introduced to the vat; it will dissolve after a few days in the vat.

Add madder root, bran, and soda ash to the warm water stir well then add indigo paste to the vat. Cover, but not tightly, and apply heat source.

Stir the pot once, or twice, a day during the reduction period with one gentle stir. If you stir the vat too often this will introduce Oxygen into the vat.

Depending on where you live, i.e., temperature and humidity levels, the vat can take anywhere from 5 – 10 days to become viable. By viable I mean ready to dye fibers.

Fermentation vats need to be kept warm while reducing. I keep my vat, a stainless steel pot that is covered with a lid, in my studio oven (gas) where the pilot light is continuously on, about 98 degrees F.

The vat needs to be kept at body temperature during the reduction phase.

If you do not have a dedicated oven, I recommend using either a heating pad, with a temperature control knob, or a high quality fish tank heater with digital temperature controls.

Chopped Madder Root

Chopped Madder Root The Bran now added to the vat. The bran floats on top of the madder root until they have been sufficiently stirred together, eventually sinking to the bottom of the vat.

The Bran now added to the vat. The bran floats on top of the madder root until they have been sufficiently stirred together, eventually sinking to the bottom of the vat. Soda Ash has now been added to the vat. The vat has a foamy look from the bubbling action of the soda ash. The mixture has been blended, to ensure that the soda ash does not solidify on the bottom of the bucket.

Soda Ash has now been added to the vat. The vat has a foamy look from the bubbling action of the soda ash. The mixture has been blended, to ensure that the soda ash does not solidify on the bottom of the bucket.WARNING: Always add your acids and bases to water, never the other way around! Doing so can result in harmful reactions that can cause injury.