Natural Indigo Fermentation Vat

Copyright 2006

Kimberly Baxter Packwood

Natural Indigo Fermentation Vat Mini-Vat Instructions

1.0 ounce Natural Indigo Ground

0.5 ounce Madder Root cut into fine pieces

0.5 ounce Bran (Wheat works best, Oat will also work)

3.0 ounce Soda Ash

Stainless Steel, or Enamel, Pot. A plastic bucket may be substituted for the pot, be sure that has a tight fitting lid.

Place warm water, not boiling, into pot, preferably one that holds more than 2 gallons of water.

WARNING: Wear respirator when working with ground indigo, anything in powdered form will float easily in the air making it easily inhaled. This is not good for your lungs!

WARINGING: Soda Ash is highly caustic, wear gloves and dust mask when handling soda ash. Avoid contact with skin.

Dissolve ground indigo in warm tap water, enough to cover and make a rough paste.

Note: The ground Indigo will float at the top of the vat if just thrown into the water make your paste first. The indigo at this point is not completely dissolved, once introduced to the vat; it will dissolve after a few days in the vat.

Add madder root, bran, and soda ash to the warm water stir well then add indigo paste to the vat. Cover, but not tightly, and apply heat source.

Stir the pot once, or twice, a day during the reduction period with one gentle stir. If you stir the vat too often this will introduce Oxygen into the vat.

Depending on where you live, i.e., temperature and humidity levels, the vat can take anywhere from 5 – 10 days to become viable. By viable I mean ready to dye fibers.

Fermentation vats need to be kept warm while reducing. I keep my vat, a stainless steel pot that is covered with a lid, in my studio oven (gas) where the pilot light is continuously on, about 98 degrees F.

The vat needs to be kept at body temperature during the reduction phase.

If you do not have a dedicated oven, I recommend using either a heating pad, with a temperature control knob, or a high quality fish tank heater with digital temperature controls.

Chopped Madder Root

Wheat Bran

Madder Root added to warm water in bucket. Initially it floats at the top of the water’s surface.

The Bran now added to the vat. The bran floats on top of the madder root until they have been sufficiently stirred together, eventually sinking to the bottom of the vat.

Soda Ash has now been added to the vat. The vat has a foamy look from the bubbling action of the soda ash. The mixture has been blended, to ensure that the soda ash does not solidify on the bottom of the bucket.

WARNING: Always add your acids and bases to water, never the other way around! Doing so can result in harmful reactions that can cause injury.

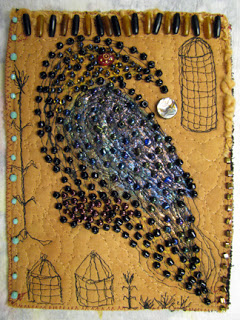

Natural Indigo added to the vat. The Madder and Bran are still floating at or near the waters surface. The indigo while made into a paste, does not want to dissolve in the water as you can see from the globs hanging on the sides of the bucket.